After the BLDC motor driver circuit, had been introduced, its demand and use have increased past the mid- 20th century. Be it because of its flexibility that it can be converted into small size, or is it because it is much lighter than the conventional dc motor with brushes, the product is in the most preferred list of people.

The device demands information about the rotor- position to set the favorable commutation angle. And, for this purpose, a Hall effect sensor is employed in the project. However, doing so can increase the overall project cost. And, therefore we often prefer a sensor-less option. A simple DRV10866 driver IC just serves our purpose right. It drives a BLDC rotor and eradicates the use of position sensors in the circuit. The fact which makes this project quite interesting is that the speed of the fan used in this project can be altered smoothly unlike the speed changing mechanism in a normal AC fan.

Circuit and Working of BLDC Motor Driver Circuit

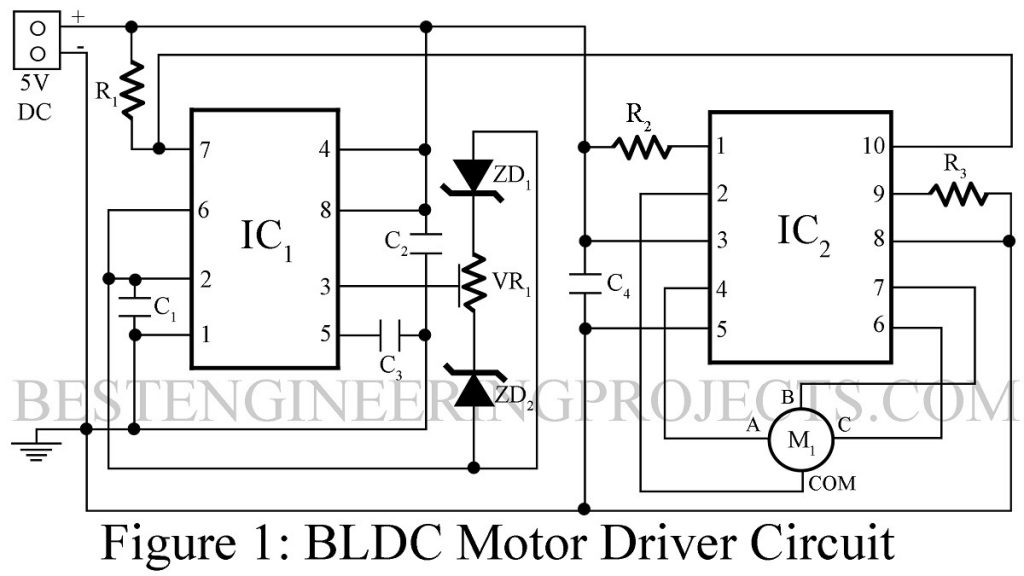

The entire layout of the above-proposed project; BLDC Motor Driver Circuit is given in fig.1. As illustrated in the figure, the chief component is a NE555 (IC1) and other components like a DRV10866 (IC2) accompany the chief component to reach the goal of the project.

IC2 that controls the fan does the work of driving a small three-phase BLDC motor (M1). Probably you get it now, the circuit depicts a clear picture of a sensor-less three-phase motor driver. The circuit also includes power MOSFETs that have a current driving capacity of up to 680mA peak value. Keeping the concept of the project in mind, IC2 is selected since it is manufactured for low noise and low component-count fan-motor drive applications.

To keep control of the three-phase motor, a 150° sensor-less back emf scheme is used.

Talking about the BLDC Motor Driver Circuit setup details, as stated earlier IC2 is the central- component. Pin 1 of IC2 is fixed with a 100k pull-up resistor (R2). Similarly, pins 2,4,6, and 7 of IC2 are connected to common, phase A, phase C, and phase B of the BLDC motor, respectively. Two ICs; IC1 and IC2 are bonded by the path established by connecting pin 10 of IC2 with pin 7 of IC1. This bond ensures the production of pulse-width modulated (PWM) signal from IC1 which helps to control the speed of the BLDC motor incorporated in the circuit.

Thus, the PWM signal reaches pin 7(DIS) of IC1 and is available at that pin only not at the assigned output pin 3 of that particular IC. The duty cycle of the PWM signal is recorded to be approximately 25kHz. It can be varied between 5% to 95% with the use of a potentiometer VR1. Changing the duty cycle of the PWM signal also affects the speed of the BLDC motor. A clockwise variation in potentiometer lowers the duty cycle and slows down the fan speed and anti-clockwise variation increases both duty cycle and fan speed.

Construction of BLDC Motor Driver Circuit

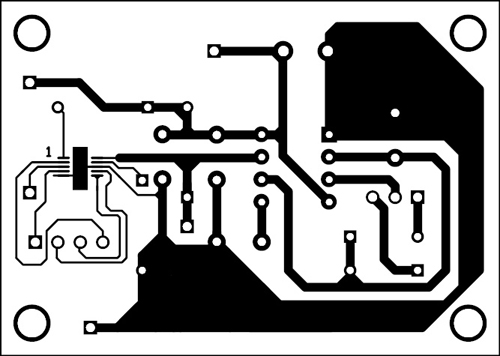

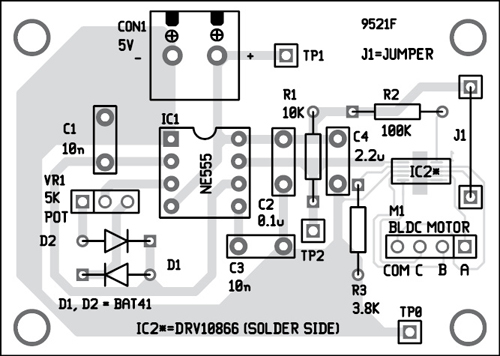

Figure 2 shows the actual-size, single-side PCB design for the BLDC motor driver circuit. Figure 3 depicts the component layout for the same. As shown in the BLDC motor driver circuit place all the components in the assigned order and avoid any possible errors which may degrade the implementation process. As shown in the figure, IC2 must be fixed on the solder side of the PCB.

Click Here To Download PCB Design

Figure 2: Solder Side PCB Design for BLDC Motor Driver Circuit

Figure 3: Component Side PCB for BLDC Motor Driver Circuit

Once the assembling process is completed, check for possible errors and then provide the circuit with a 5V power at the CON1 connector.

PARTS LIST OF BLDC MOTOR DRIVER CIRCUIT

| Resistor (all ¼-watt, ± 5% Carbon) |

| R1 = 10 KΩ

R2 = 100 KΩ R3 = 3.8 KΩ VR1 = 5 KΩ |

| Capacitors |

| C1, C3 = 10nF (Ceramic Disc)

C2 = 0.1 µF (Ceramic Disc) C4 = 2.2 µF (Electrolytic Capacitor) |

| Semiconductors |

| IC1 = NE555 (Timer IC)

IC2 = DRV10866 (3-Phase, Sensorless BLDC Motor Driver) ZD1, ZD2 = BAT41 (Schottky Diodes) |

| Miscellaneous |

| M1 = Brush Less DC Motor (BLDC motor) |

I m interested in single phase 12v and 24 volt dc BLDC motor circuit 15 watt output ,with aur without hall sensor .pl help.

Thank you sir you made my day, i was searching for bldc motor driver circuit since long and, even i assemble various circuit available over internet but every time i fail either they are not working or not giving desire output.

I made this circuit and get perfect output.

thank you bestengineeringproject once again.